PROJECTS

Recent Projects

Narre Warren

2020/21 – ARENA ARP

Advancing Renewables with PCM Energy Storage

This project received funding from ARENA as part of ARENA’s Advancing Renewables Program.

Application

Heat Pump with Energy Storage

Sector

Process Heating & Cooling/Cold Storage

Technology

- CO2 R744 Heat Pump

- Phase Change Material Thermal Energy Storage (PCM TES)

Advanced Control Forecasting Algorithm (ACFA)

Brief

Montague, one of Australia’s largest fruit growers, is currently constructing an expansive new multi-use fruit processing facility in Narre Warren North. The complex will process over 260,000,000 pieces of fruit annually which will be distributed to markets across Australia and the world.

The energy use in apple production facilities is extremely high. A 2016 study by the Apple & Pear Australia Ltd, funded by the Department of Resources Energy & Tourism, concluded that refrigeration represents about 65% of total electricity costs for a typical grower with the remainder comprising of irrigation costs (18%), pack-house operations (8%), and lighting (5%).

Glaciem’s CO2 heat pump is the largest CO2 only heat pump in Southern Hemisphere and negates the need to use LPG for heating water. The heat pump cools the sites glycol loop while simultaneously generating 83˚ C hot water. Integration of thermal storage units allow continuous high efficiency heating even during low ambient conditions.

Scope

- install a new R744 heat pump to provide 714kW Cooling 1.1MW heating (heating water 35˚C – 83˚ C)

- install a 2x Thermcold DYN 900 unit to provide 4MWh of thermal energy storage

- Integrate heat pump and PCM TES with sites new ammonia/glycol refrigeration plant

- integrate this system with on-site the solar PV;

- use -6 degrees PCM and propylene glycol as the heat transfer fluid;

- integrate ACFA with the site’s SCADA to allow the system to dynamically control the heating and cooling loads and maximise the usage and storage of the site’s renewable energy.

Mount Gambier

2020

Application

Commercial Building Heating & Cooling

Sector

HVAC

Technology

CO2 Only Cooling and Heating

Brief

Oatmill Cinema is a cinema complex based in a historic building in Mount Gambier.

The building’s ageing Heating Ventilation and Air Conditioning (HVAC) equipment (>20 years) operated on ozone depleting HCFC refrigerant R22.

R22 refrigerant has been phased out under the Montreal Protocol,with no virgin imports into Australia since 2016. This has seen the price of R22 increase to over $400/kg. The building owners are left with the predicament of when replacing this aging equipment of which refrigerant to change to. The most common replacement on the markets contain HFC refrigerants which are also been phased out due to their high Global Warming Potential (GWP).

Oatmill Cinema’s owners worked with Glaciem Cooling to evaluate the energy demands of the cinema complex. A detailed economic analysis of energy demands and modeling of the performance of a new system was performed by Glaciem.

Scope

Glaciem’s solution was to install the Southern Hemisphere’s first direct expansion CO2 only system cable of providing simultaneous heating & cooling.

Due to the unique nature of the design the buildings existing HVAC infrastructure could still be utilised with only the heating & cooling coils requiring replacement. The utilisation of the existing HVAC infrastructure resulted in a >45% saving on the installation cost. The new system is also estimated to reduce heating and cooling electrical operating cost 56%

Pernod Ricard Winemakers

Rowland Flat

2019/20 – ARENA ARP

Advancing Renewables with PCM Energy Storage

This project received funding from ARENA as part of ARENA’s Advancing Renewables Program.

A virtual walkthrough of the completed installation is available here.

Application

Barrel Storage, Packing Areas

Sector

Process Cooling

Technology

Phase Change Material Thermal Energy Storage (PCM TES)

Advanced Control & Forecasting Algorithm (ACFA)

Brief

Pernod Ricard’s Roland Flat facility is located in the Barossa Valley, SA, and has winemaking, wine storage and packaging capability. Significant refrigeration is used to process the harvest during summer months from January to April. Refrigeration loads decrease by about 70% outside of this period. The existing refrigeration plant, Frig 9, operates year round, providing process cooling, barrel storage and air conditioning and has been identified as optimal for thermal storage integration.

This project involves the integration of a Glaciem thermal storage unit operating on renewable energy with the existing Frig 9 ammonia refrigeration plant to optimise process cooling techniques in a primary production context and reduce exposure to peak electricity costs.

Scope

- install a new Thermcold DYN 900 unit to provide 2.6MWh of thermal energy storage

- Integrate PCM TES with sites existing ammonia refrigeration plant

- integrate this system with virtual and on-site renewable assets;

- use 0 degrees PCM and Dynalene HC as the heat transfer fluid;

- integrate ACFA with the site’s Building Management System (BMS) to allow the system to dynamically control the usage and storage of the site’s renewable energy.

Reef HQ, Townsville

2019/20 – ARENA ARP

Advancing Renewables with PCM Energy Storage

This project received funding from ARENA as part of ARENA’s Advancing Renewables Program.

A virtual walkthrough of the completed installation is available here.

Application

Heating Ventilation Air Conditioning (HVAC)

Sector

Commercial Buildings

Technology

CO2 Heat Pump

Phase Change Material Thermal Energy Storage (PCM TES)

Advanced Control & Forecasting Algorithm (ACFA)

Brief

A large portion of Reef HQ energy consumption is used by the existing HFC refrigeration chillers. These chillers provide chilled water-based air conditioning for the building and also cool 4 million litres of chilled seawater in the two main Aquarium tanks which are maintained at 28°C for optimum marine life conditions. The site currently has 256kW of installed PV and a zero-export limit.

The installation of PCM TES, a CO2 Heat pump & ACFA will store any access renewable energy, thus drastically reducing operating costs, maximising the economic potential of renewable energy assets and reduce direct and indirect CO2 greenhouse gas emissions.

Scope

- install a new Thermcold DYN 420 unit to provide 1MWh of thermal energy storage using 0 degrees PCM

- integrate this system with on-site storage of up to 75% of the solar PV;

- install a new CO2 heat pump to run in parallel with the existing HVAC-R systems;

- use 0 degrees PCM and Dynalene HC as the heat transfer fluid;

- integrate ACFA with the site’s Building Management System (BMS) to allow the system to dynamically control the usage and storage of the site’s renewable energy.

- Heating Capacity 48 kWr

- Total Volume 80°C water 1000litres/day

Misty Downs Dairy

Misty Downs Dairy

Mt Compass SA, 2019/20

A virtual walkthrough of the completed installation is available here.

Application

- Milk Cooling

Hot Water Generation

Sector

Process Cooling

Technology

CO2 Heat Pump / PCM TES

Brief

Project aim is to reduce milk spoilage by rapid cooling of milk, reduce grid electricity reliance, increase energy efficiency

Scope

- Daily Milk Production 1000 Litres/day

- Total Daily Cooling Energy 283 kWh

- Solar PV 20 kW

- PCM TES Capacity 293 kWh

- Cooling Capacity 43 kWr

- Heating Capacity 48 kWr

- Total Volume 80°C water 1000litres/day

Murray River Organics

Mildura VIC, 2019

Application

High Capacity Blast Freezer for dried fruit

Sector

Process Cooling

Technology

-25°c Flooded Cascade CO2

Brief

- R22 (HCFC) replacement

- low carbon footprint

- Reduced HFC levy exposure

- Efficiency / Payback

Scope

- 70 kWr 134a/CO2 Cascade

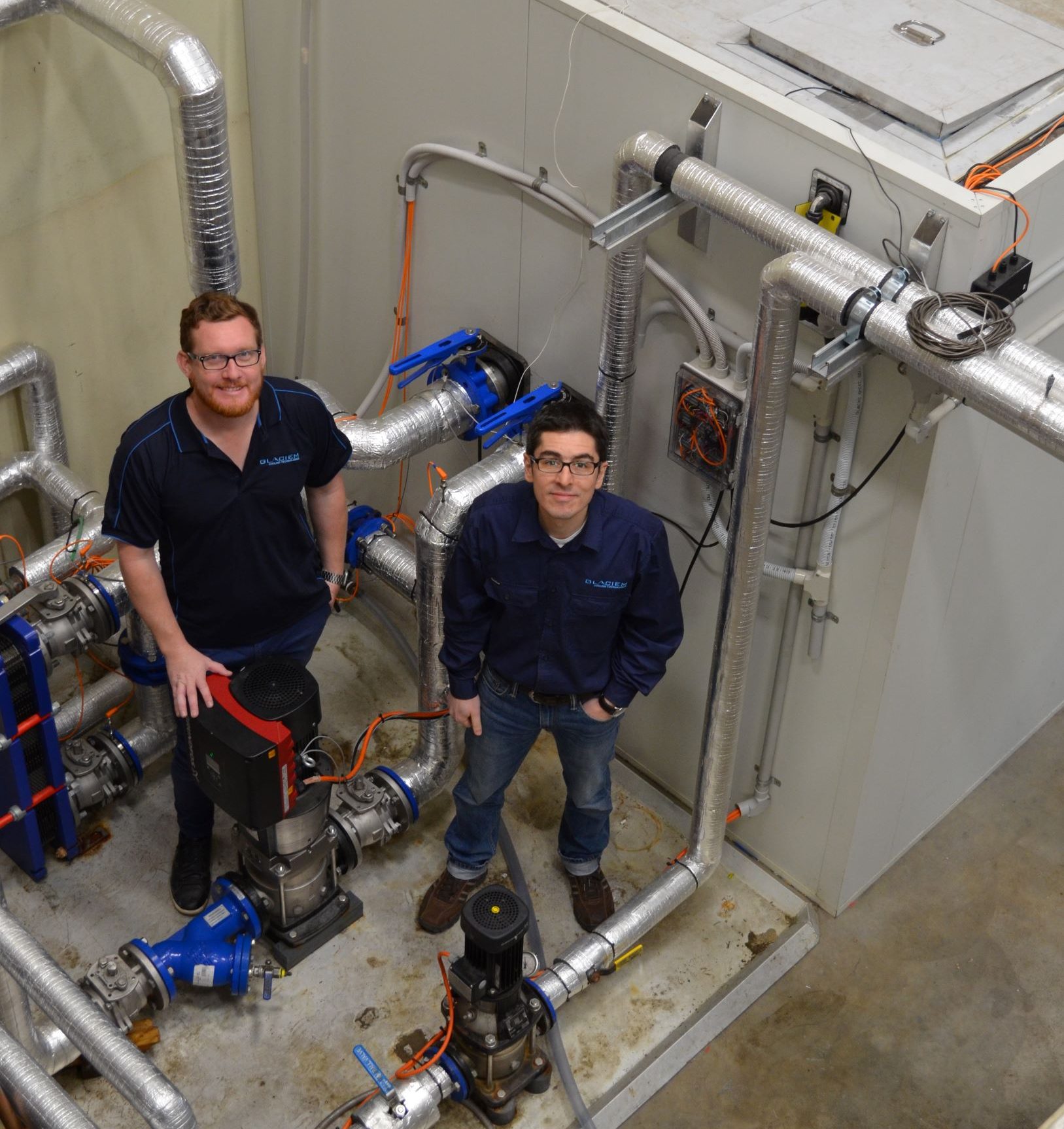

Glaciem Test Rig

Mawson Lakes SA, 2017

Application

DPCO2 & TES Test Rig

Sector

Research and Development

Technology

DPCO2 Refrigeration

-6 degrees C PCM

Brief

- The R & D test rig was developed with ARENA support to demonstrate capture of renewable energy with TES

- The test rig has also characterized the performance of our patented DPCO2 refrigeration system

Scope

- 1 MWh TES

‘The Bend’ Motorsport Park

Tailem Bend, 2018

Application

Freezer and cool room

Sector

Cold Storage

Technology

DPCO2 Refrigeration

-6 degrees C PCM

Brief

- Demonstrate DPCO2

- Demonstrate -6 degree PCM

- Demonstrate integrated coooling

- Efficiency / Payback

Scope

- 23 kWr

- 100 kWh TES

Woolworths

Whyalla, SA

Install Date

2022

Application

- Commercial Building Heating & Cooling

Sector

HVAC

Technology

R744 (CO2) Heat Pump

Size

- Cooling Capacity 326kW

- Heating Capacity 228kW

Brief

The buildings ageing Heating Ventilation Air Conditioning (HVAC) equipment (>20 years) operated on ozone depleting HCFC refrigerant R22.

R22 refrigerant has been phased out under the Montreal Protocol and no virgin with no virgin imports into Australia since 2016, this has seen the price of R22 increase to over $400/kg. The building owners are left with the predicament of when replacing this aging equipment of which refrigerant to change to, the most common replacement on the markets contain HFC refrigerants which are also been phased out due to their high Global Warming Potential (GWP).

Solution

Building on the lessons learnt from the Oatmill project Glaciem has designed a unique new system capable of simultaneous heating & cooling with extremely high efficiencies.

The CO2 heat pump is designed to provide cooling or heating to the store via an air handling unit, the heat pump can also provide simultaneous cooling and heating for dehumidification, with capacity for full air sourced heating when no simultaneous cooling available and adiabatic gas cooler when no (or insufficient) heating demand available.

Cooling is provided by Direct Expansion (DX) of liquid CO2 in the air handling unit evaporator.

Heating is achieved by desuperheating supercritical CO2 in the heating coil installed in the air handling, heat not extracted from the supercritical CO2 in the heating coil can be further cooled by the adiabatic gas cooler. The gas cooler also has two additional airside evaporator coils installed that can provide additional cooling load during heating if there is insufficient cooling load from the air handling unit cooling coil

Woolworths

Gordon

Install Date

2022

Application

Commercial Building Heating & Cooling

Sector

HVAC

Technology

R744 (CO2) Heat Pump

Size

Cooling Capacity 280kW

Heating Capacity 184kW

Brief

The buildings ageing Heating Ventilation Air Conditioning (HVAC) equipment (>20 years) operated on ozone depleting HCFC refrigerant R22.

R22 refrigerant has been phased out under the Montreal Protocol and no virgin with no virgin imports into Australia since 2016, this has seen the price of R22 increase to over $400/kg. The building owners are left with the predicament of when replacing this aging equipment of which refrigerant to change to, the most common replacement on the markets contain HFC refrigerants which are also been phased out due to their high Global Warming Potential (GWP).

Solution

Building on the lessons learnt from the Oatmill project Glaciem has designed a unique new system capable of simultaneous heating & cooling with

extremely high efficiencies.

The CO2 heat pump is designed to provide cooling or heating to the store via an air handling unit, the heat pump can also provide simultaneous cooling and heating for dehumidification, with capacity for full air sourced heating when no simultaneous cooling available and adiabatic gas cooler when no (or insufficient) heating demand available.

Cooling is provided by Direct Expansion (DX) of liquid CO 2 in the air handling unit evaporator. Heating is achieved by desuperheating supercritical CO 2 in

the heating coil installed in the air handling, heat not extracted from the supercritical CO 2 in the heating coil can be further cooled by the adiabatic gas cooler. The gas cooler also has two additional airside evaporator coils installed that can provide additional cooling load during heating if there is insufficient cooling load from the air handling unit cooling coil.

WoolWorks

Timaru NZ

Install Date

2023

Application

- Process Heating

Sector

Textile Industry (Wool Scouring)

Technology

R744 (CO2) Heat Pump

Size

Heating Capacity 712kW

Hot water flow rate: 2.27 l/s

Hot water inlet temperature: 15˚C

Hot water outlet temperature: 90˚C

Brief

Woolworks is New Zealand’s only wool scouring Service provider, operating the largest wool Scouring facility in the world.

WoolWorks washes wool so it can be processed into the next stage. The washing process is very similar to an automatic washing machine but on a much larger scale.

The wool goes through three bowls of heated water at different temperatures. The scour lines are up to 100 metres long and 5 metres wide and contain 27 cubic

metres of water, so there are significant energy costs to heat the water and run the machines. The existing system used a coil fired boiler to generate steam & hot water.

Solution

The company has been working with EECA since 2016 to reduce their energy usage. As part of that journey, their latest project will see them replacing coal with electricity to power their Timaru site in a world-leading initiative.

EECA is investing $3.63 million through the Government Investment in Decarbonising Industry (GIDI) fund, to co-fund the switch from coal to electricity at the Washdyke site near Timaru.

The GIDI funding will be used to install an electrodeboiler to produce steam and an industrial heat pump to generate hot water. The new Glaciem R744 heat pump

uses waste water as a cooling source & is able to heat 15°C to 90°C.

The project is expected to reduce over 11,000 tonnes of carbon dioxide emissions every year, the equivalent of removing 3,021 cars off the road.

Van Lier Nurseries

New Zealand

Install Date

2023

Application

Process Heating

Sector

Horticulture

Technology

R744 (CO2) Heat Pump

Size

Heating Capacity 1000kW

Hot water flow rate: 4.4l/s

Hot water inlet temperature: 35˚C

Hot water outlet temperature: 90˚C

Brief

Van Lier Nurseries is located in Riverhead, New Zealand and produces cut roses and plants. Its site at the Riverhead has a flower propagation house (13900 m 2 ) and growing house (2250 m 2 ) which are being heated up by low temperature hot water pipe heat emitters (LTHW) to maintain the space temperature between 18- 25 C.

The heating requirement of the LTHW system is provided by a natural gas boiler with nameplate capacity of 2.8 MW , while the peak heat load is around. 1.15 MW. The site also has a large stratified hot water tank of 430,000 litres capacity. This tank is used to balance the heating demand throughout the day.

Van Lier were looking for viable alternatives to natural gas boilers as part of their decarbonisation strategy.

Solution

Building on the lessons learnt from the Oatmill project Glaciem has designed a unique new system capable of simultaneous heating & cooling with extremely high efficiencies.

The CO2 heat pump is designed to provide cooling or heating to the store via an air handling unit, the heat pump can also provide simultaneous cooling and heating for dehumidification, with capacity for full air sourced heating when no simultaneous cooling available and adiabatic gas cooler when no (or insufficient) heating demand available.

Cooling is provided by Direct Expansion (DX) of liquid CO2 in the air handling unit evaporator.

Heating is achieved by desuperheating supercritical CO2 in the heating coil installed in the air handling, heat not extracted from the supercritical CO2 in the heating coil can be further cooled by the adiabatic gas cooler. The gas cooler also has two additional airside evaporator coils installed that can provide additional cooling load during heating if there is insufficient cooling load from the air handling unit cooling coil

OJJ Singapore

Jurong, East Singapore

Install Date

2022

Application

Food Processing/Food Storage

Sector

Cold Chain

Technology

R744 (CO 2 ) Booster C/W Parallel Compressors

Size

Level 1 2 Stage Booster C/W Parallel Comps 13kW LT 52kW MT 147kW HT

Level 3 2 Stage Booster C/W Parallel Comps 17kW LT 83kW MT 300kW HT

Level 4 2 Stage Booster C/W Parallel Comps 37kW LT 41kW MT 345kW HT

Level 5 2 Stage Booster C/W Parallel Comps 185kW LT 100kW MT 205kW HT

Level 6 2 Stage Booster C/W Parallel Comps 177kW LT 22kW MT 280kW HT

Brief

OJJ Foods is one of the largest processors and distributors of chilled and frozen pork in Singapore. It supplies pork in bulk and consumer-friendly packs to major supermarkets under their house brands, established brand name restaurant chains as well as hawkers & wet market stalls OJJ Foods new is a six-storey, 18,000sqm food processing facility located in Jurong East Singapore.

The new facility comprises a fully automated refrigerated ASRS warehouse, chiller and freezer cold rooms, central kitchen and other production and ancillary offices.

A project of this size would normally be a two stage ammonia system, however concerns were raised around the safety of ammonia. HFC & HFO refrigerants.

Solution

Working in partnership with the Far East Group (FEG) Glaciem’s solution comprises of five independent R744 booster systems delivering >2000kW of refrigeration with temperature ranges from -42°C to 10°C.

Historic Projects

Runda Medical

Runda Medical

Shanghai, 2016

Application

Blood & Vaccine Storage

Sector

Cold Storage

Technology

R134a/CO2 Hybrid Cascade (flooded)

Brief

- Precise Temperature Control

- Reliability

- Efficiency/payback

Scope

- low temp 65kW

- medium temp 309kW

Parilla Premium Potatoes

Parilla Premium Potatoes

SA, 2013

Application

Long Term Potato / Onion Storage

Sector

Cold Storage

Technology

-11°c PCM

Low Charge ammonia plant

Brief

- R22 (HCFC) replacement

- low Carbon Footprint

- Reduced HFC levy exposure

- Efficiency / Payback

Scope

- 240kWr

- 4 x 770kWh (3080kWh) TES