Thermal Energy Storage Solutions

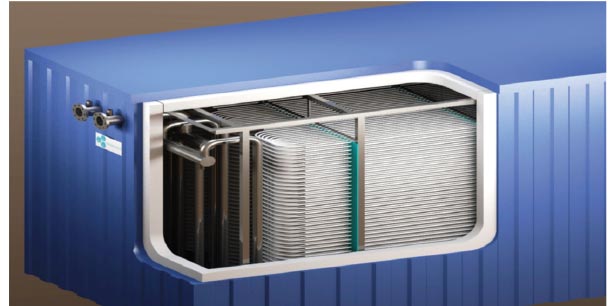

In ThermCOLD, Glaciem offer a unique selection of Thermal Energy Storage (TES) solutions.

Incorporating Eureka Prize Winning Phase Change Materials (PCM), these solutions are targeted at providing high efficiency thermal energy storage at temperatures suited to a range of commercial and industrial applications. ThermCOLD is available in 0ºc, -6ºc & -11ºc temperature brackets.

Thermcold is easily incorporated into existing refrigeration infrastructure and is modular, allowing for an appropriately sized system, whatever the requirement. Thermcold incorporates cutting edge Dynamic Melt technology, greatly increasing heat transfer efficiency allowing for faster charge and discharge cycles.

Thermcold is well suited to being incorporated with solar PV, and can drastically improve end user’s energy cost profile.

Thermal energy storage (TES) allows the transfer and storage of heat energy, by means of a thermal reservoir. The thermal energy stored can then be used later. A typical example used for cooling is to run a refrigeration plant overnight using cheaper off peak electricity, then during the day the refrigeration plant is cycled off and the energy used in the ice is used for cooling, thus avoiding using more expensive peak electricity. Glaciem’s thermal energy storage solution, Thermcold, makes use of special phase change materials to allow thermal storage at previously unheard of temperatures.

The recent volatility in global and domestic energy markets is driving a fundamental rethink in how we access and use energy. Electrical battery solutions are now giving people the opportunity to store energy captured now, for use later. This makes sense if an electrical end use exists, but what if that end use was cooling? What kind of battery allows us to store energy now, to give us highly efficient ‘cold’ later?

Answer – Glaciem’s Thermcold. A revolution in ice or thermal ‘battery’ technology.

Thermcold’s groundbreaking Phase Change Material and Dynamic Melt system allow users to shift the energy load from the high daytime electricity rates to the lower nighttime electricity rates. How? Simply by recharging the Thermcold unit when energy is at its cheapest, and then using this stored ‘cold’ instead of the grid during peak times. This can reduce refrigeration electricity costs by up to 50% by charging during non-peak hours to discharge during peak-cost hours. Thermcold units are approximately 36% of the installed cost electrical storage (Batteries) and it makes sense to use the lowest cost option.

Additionally, flexibility around when to run refrigeration means cooling can run at night, using less energy due to lower ambient temperatures.

Exciting hybrid energy systems are made possible through Thermcold technology. Its energy storage capability resolves the mismatch between generation hours and electricity use so that solar and wind power can form an even larger slice of the national generation grid. Making ice with the sun and the wind!

This same flexibility can help smooth out electricity use, reducing the need for expensive, peak-driven infrastructure, and for extra fossil-fuel generation of power during daylight hours. This reduced ‘peakiness’can in some cases lead to reduced maximum demand (kVA) electricity supply charges and reduce the risk of receiving penalties for exceeding allowable total (kVA) demand.

Thermcold’s thermal storage system can also form part of a robust blackout management system. When combined with minor electrical storage to manage control systems, pumps and lighting, a combination of a renewable energy source and Thermcold thermal storage technology can allow sites to manage during periods of grid outage, helping avoid food or other perishable losses.

Glaciem Cooling Technologies thermal storage system Thermcold utilises the development of new Phase Change Materials (PCM’s) to provide a revolutionary breakthrough that can significantly reduce energy costs for medium & low temperature refrigeration applications.

These special Phase Change Material (PCM)PCMs were devolved developed by UniSA and won winner of the Australian Museum 2015 ANSTO prize for Innovative use of Technology.

The technology has been fully commercialized by obtaining an Australian government CleanTech grant in 2013 and a 3200kW/h Thermal Energy Storage (TES) system has been operating successfully at an Onion and Potato storage facility in South Australia.

You can read more in our Parilla Case Study.

Medium & low Temperature Food Storage (0⁰C to -21⁰C) using secondary heat transfer fluids.

Thermal Battery; Potential to store excess electricity generated by Solar PV or Wind in the form of thermal energy

Ideal for increasing winery refrigeration plant efficiency at low loads outside vintage

Ideally suited for food process requiring –6⁰C glycol temperatures

Phase change materials (PCM) are substances that absorb and release thermal energy during the process of melting and freezing. When a PCM freezes, it releases a large amount of energy in the form of latent heat at a relatively constant temperature.

The most commonly used PCM is water/ice. Working closely with the University of South Australia, Glaciem is on the cutting edge of PCM research and development. Advances in the composition of these materials are allowing Glaciem’s Thermcold ice battery technology to deliver reliable cooling at temperatures far outside the typical thermodynamic limits of water/ice.

Glaciem Solutions – ThermCOLD Thermal Energy Storage

ThermCOLD 0ºc

Fresh water TES ideal for food processing and chilled water applications

ThermCOLD -6ºc

Our -6ºc unit is perfect for processes at or just under 0ºc

ThermCOLD -11ºc

-11ºc Seriously cold for incorporation with freezer systems

0ºc TES – Perfect for processes such as ferment control

Modular construction allowing for load matching

Dynamic melt system allows for rapid discharge

>5 times the energy density of chilled water

Available with Smart Control Logic

Easily integrated with existing refrigeration systems

Maximises the benefits of renewable energy installations

-6ºc TES – Perfect for proccesses ~0°c such as coupling with cold storage and cool rooms

Eureka Prize winning Phase Change Materials

Modular construction allowing for load matching

Dynamic melt system allows for rapid discharge

>5 times the energy density of chilled water

Available with Smart Control Logic

Easily integrated with existing refrigeration systems

Maximises the benefits of renewable energy installations

-11ºc TES – Perfect for proccesses well under zero such as coupling with freezer systems

Eureka Prize winning Phase Change Materials

Modular construction allowing for load matching

Dynamic melt system allows for rapid discharge

>5 times the energy density of chilled water

Available with Smart Control Logic

Easily integrated with existing refrigeration systems

Maximises the benefits of renewable energy installations